Exploring the Marvels of Markforged 3D Printers: Capabilities and Benefits

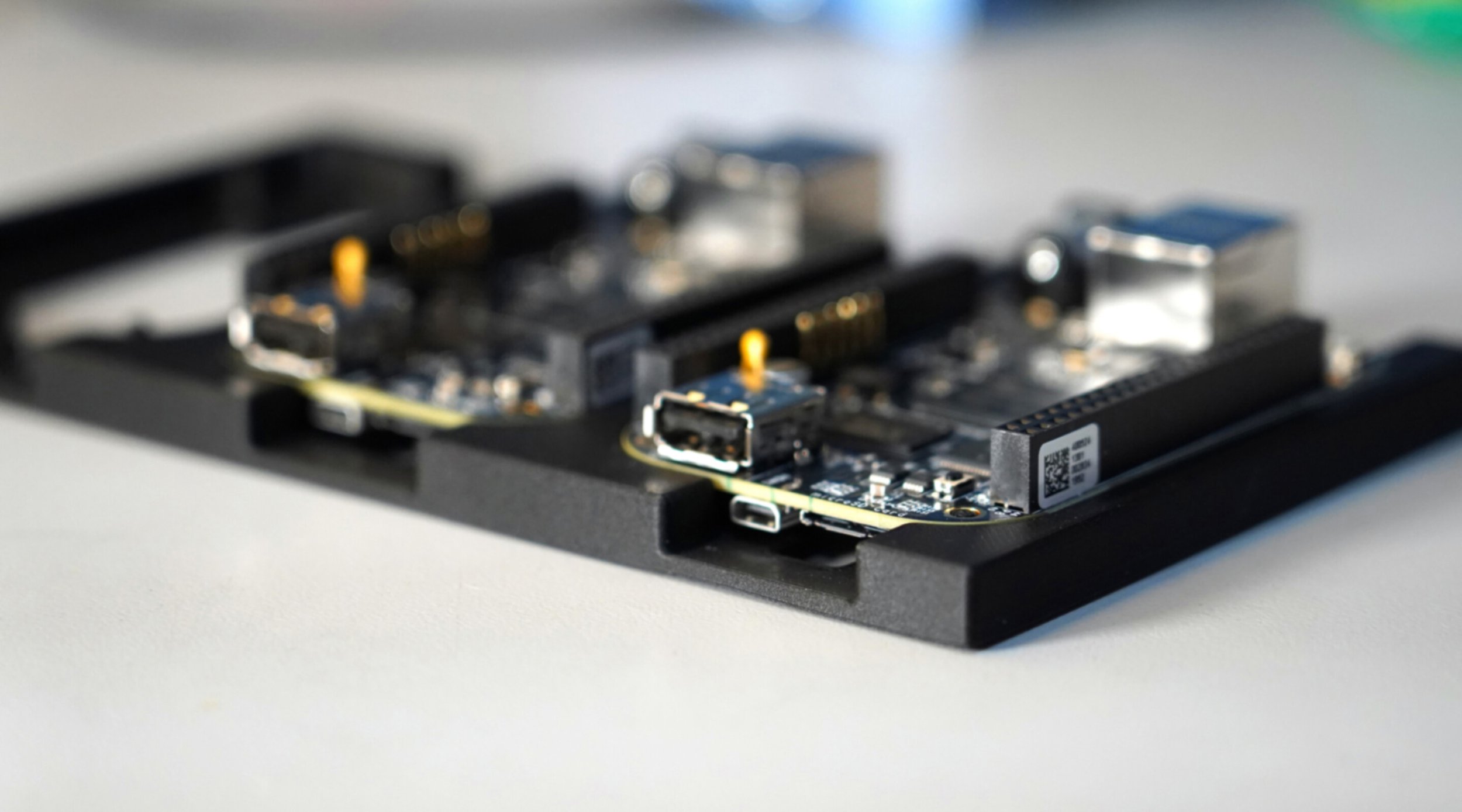

AE Components is excited to announce that we have recently acquired a Markforged 3D printer, to further broaden our manufacturing capabilities. In the ever-evolving world of 3D printing, Markforged has emerged as a standout player, pushing the boundaries of what's possible with additive manufacturing. Markforged 3D printers are renowned for their exceptional capabilities, making it a great addition to our workshop. In this blog, we will delve into the remarkable capabilities and advantages of Markforged 3D printers.

Capabilities of Markforged 3D printers

1. Precision and Strength

Markforged 3D printers are known for their precision in printing parts and components, making it the perfect edition to our workshop. This is achieved through a combination of advanced materials and technology. Markforged printers can create incredibly detailed and intricate designs, and are recognised for their ability to print strong and durable parts. This is crucial for industries such as aerospace and automotive, where parts must meet stringent standards for both strength and precision. Other industries include power generation, mining, rail, electrical applications, oil and gas, marine, construction, and defence.

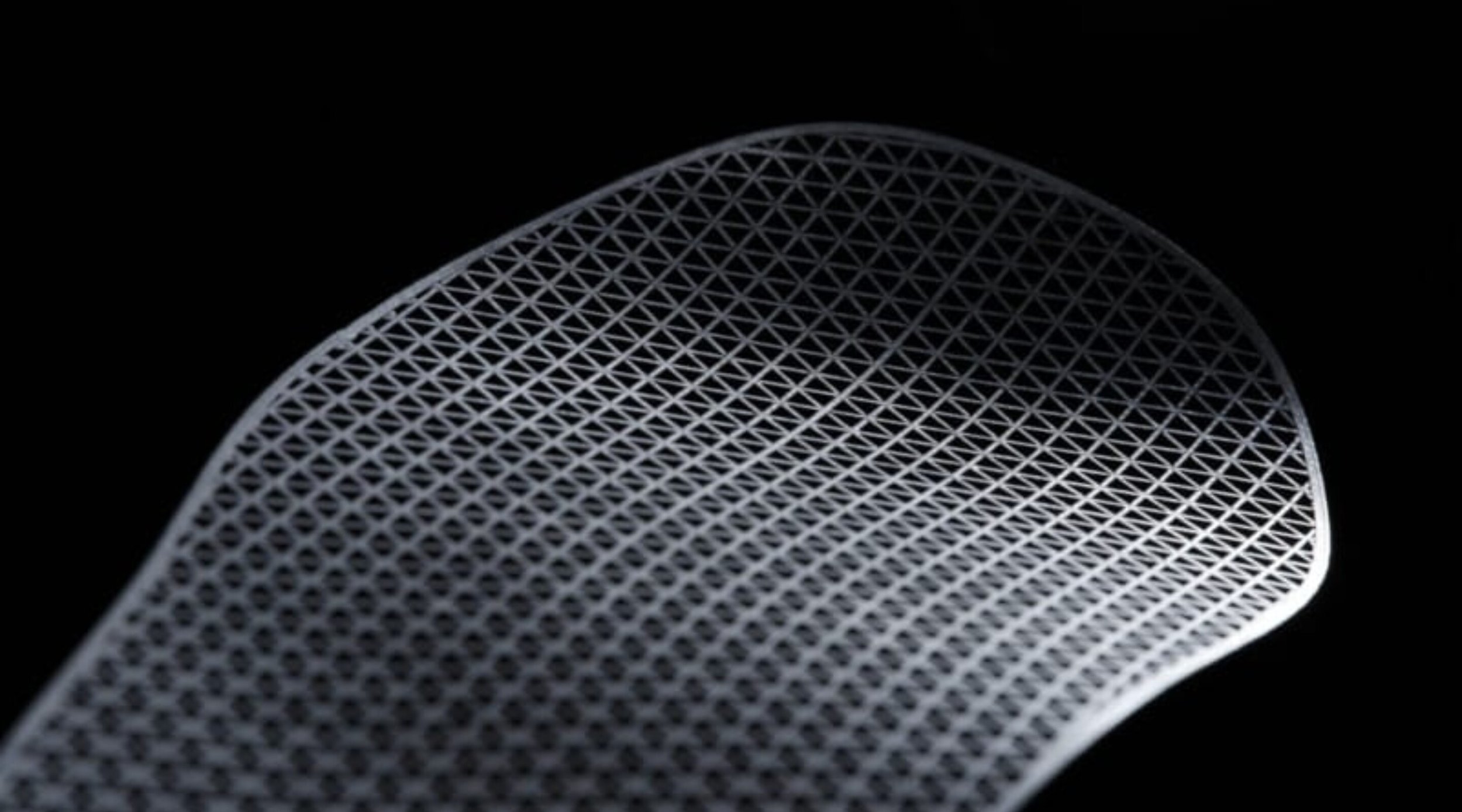

2. Additive Manufacturing with Composite Reinforcements

One of the standout features of Markforged 3D printers is their compatibility with a wide range of composite filler reinforcement materials. They can work with reinforcement materials like carbon fiber, Kevlar, and fiberglass, allowing the production of parts with enhanced strength-to-weight ratios. This capability is invaluable in industries where lightweight, yet robust components are essential, such as manufacturing, robotics, and defense.

3. High-Quality Surface Finish

Markforged 3D printers are also celebrated for their ability to produce parts with an exceptional surface finish. This is critical for applications where aesthetics matter, such as consumer goods and the automotive industry.

Benefits of Markforged 3D printers

1. Cost Savings

Markforged 3D printers can lead to significant cost savings through the production of intricate designs, reducing material waste, and minimizing the need for expensive tooling. Markforged 3D printers are changing the industry by providing an economical approach to prototyping and manufacturing.

2. Design Freedom

The capabilities of Markforged 3D printers offer designers and engineers design freedom. They can create complex, lightweight structures that were previously unattainable with traditional manufacturing methods. This leads to innovative product design and improved product performance.

3. Sustainability

3D printing, in general, is more sustainable than traditional manufacturing, as it reduces material waste. Markforged 3D printers take this a step further by enabling the use of composite materials and lighter components, which can lead to energy and resource savings.

Markforged 3D printing materials

Onyx - Flexural strength: 71 MPa

Onyx is a micro carbon filled Nylon. Onyx is 1.4 times stronger than ABS and can be reinforced with continuous fibre (carbon fiber, Kevlar, and fiberglass). Onyx is known for its superior chemical resistance, heat tolerance, and surface finish.

Onyx FR - Flexural strength: 71 MPa

Onyx FR (fire retardant) is a blue card certified UL94 V-0 material that possesses similar mechanical properties to Onyx. Its primarily used in applications in which flame retardancy, light weight, and strength are required.

Onyx ESD - Flexural strength: 83 MPa

Onyx ESD is a static dissipative safe variant of Onyx. Whilst meeting stringent ESD safety requirements, Onyx ESD offers excellent strength, stiffness, and surface finish. It’s best used in applications that require ESD safe materials.

Precise PLA and Nylon - Flexural Strength: 50 MPa

PLA (Polylactic Acid) is a cost-effective option for non-functional prototyping. Markforged Precise PLA is ideal for design iterations, fit checks, concept models, and visual-only parts that are not mechanically demanding. Precise PLA is available in eight different colours (black, grey, yellow, red, blue, orange, green and white) to create colour-coded prototypes, tool holders, and keep out zones.

Nylon parts are smooth, non-abrasive, and easily painted. They can be reinforced with any continuous fibre and work best for non-marrying work holding, repeated handling, and cosmetic parts.

Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts.

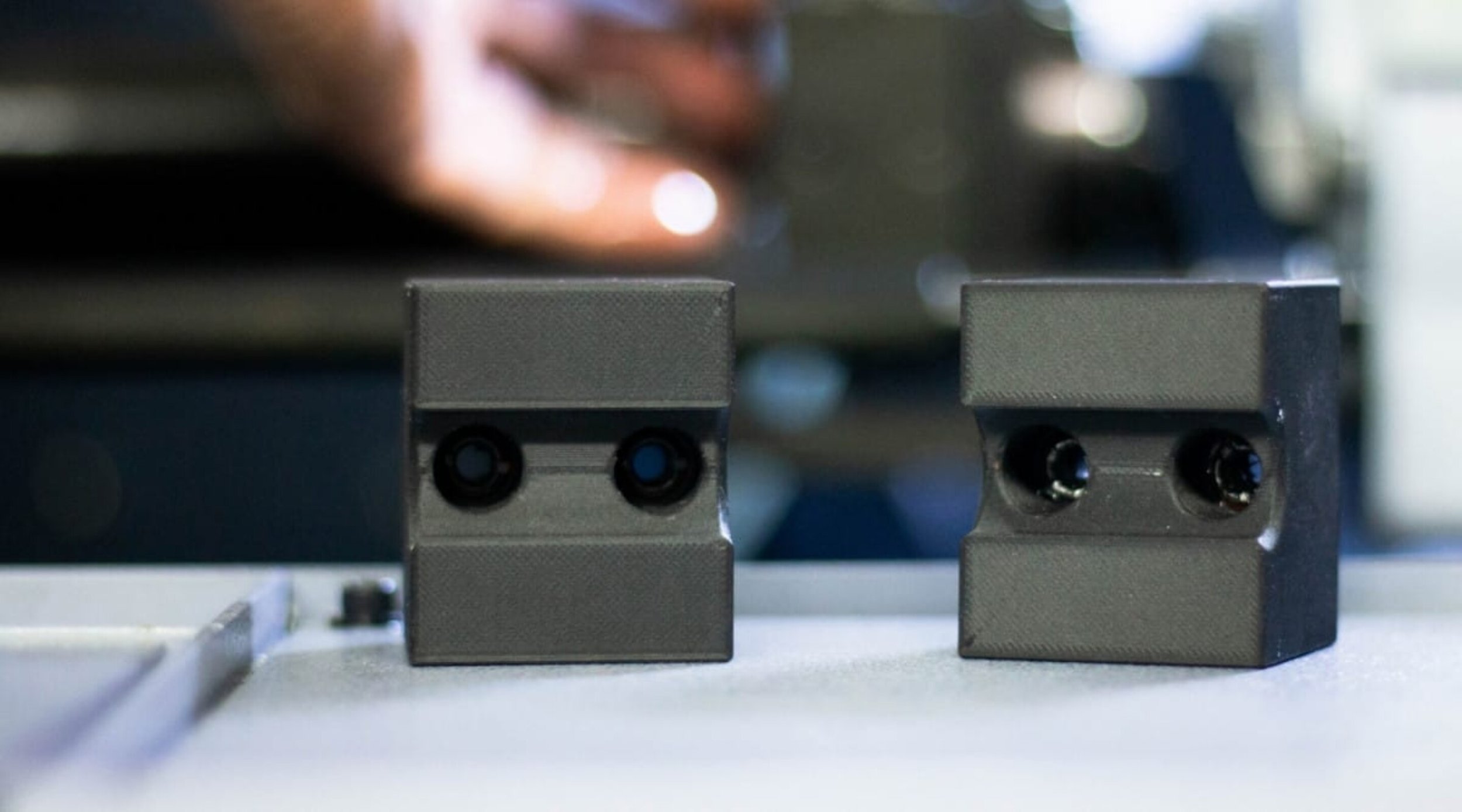

How AE Components uses Markforged 3D Printer

Markforged 3D printers have revolutionised the world of additive manufacturing with their remarkable capabilities and numerous benefits. From precision and strength to composite materials, these printers offer a wide range of solutions for various industries. At AE Components, we rely on our 3D printer to create industrial-grade manufacturing jigs, jaws, tools, fixtures, and end-use parts. Using the right materials, our Markforged 3D printer can print custom parts with unique strength.

Should you use 3D Printing in your next project?

Our team at AE Components can assist you with all Markforged 3D Printer enquires. To find out more information, get in touch with us today.

Drop us a line at [email protected] or call us on (08) 9361 2772.