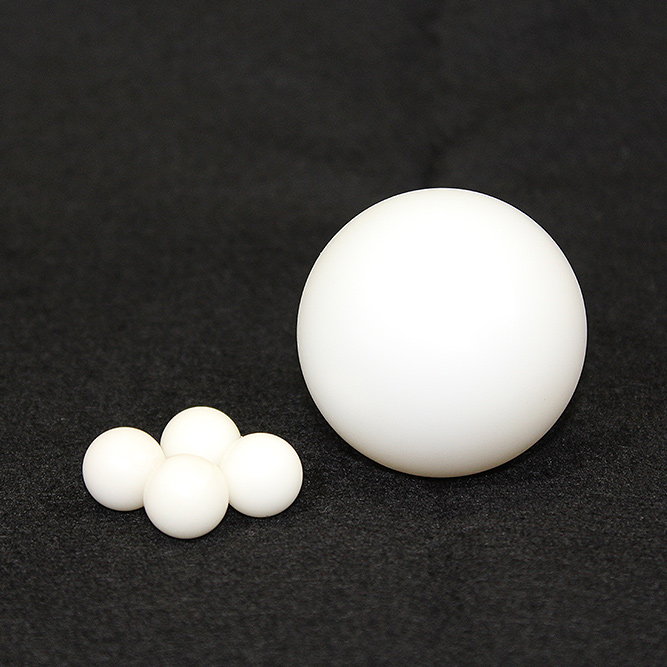

Acetal

AE stocks Ertacetal® C in colours natural and black.

The acetal copolymer (POM-C) is more resistant against hydrolysis, strong alkalis and thermal-oxidative degradation than the Acetal homopolymer (POM-H). The latter however has a higher mechanical strength, stiffness, hardness and resistance to creep, as well as a lower thermal expansion rate and often presents better wear resistance. Ertacetal® is very well suited for machining on automatic lathes and is recommended for mechanical precision parts.

Acetal is available in rod, tube and sheet, cut to size or machined to customer specification.

Main Characteristics of Acetal

High mechanical strength, stiffness and hardness

Excellent resilience

Good creep resistance

High impact strength, even at low temperatures

Very good dimensional stability

Good sliding properties

Excellent machinability

Physiologically inert (suitable for food content)

Applications

Gear wheels with small modulus

Cams

Heavily loaded bearings and rollers

Bearings and gears with small clearances

Valve seats

Snapfit assemblies

Variety of dimensionally stable precision parts for machine construction

Insulating components for electrical engineering

Parts which operate continuously in water of 60˚C to 80˚C

Related products

Share this product